Product description

Product Overview

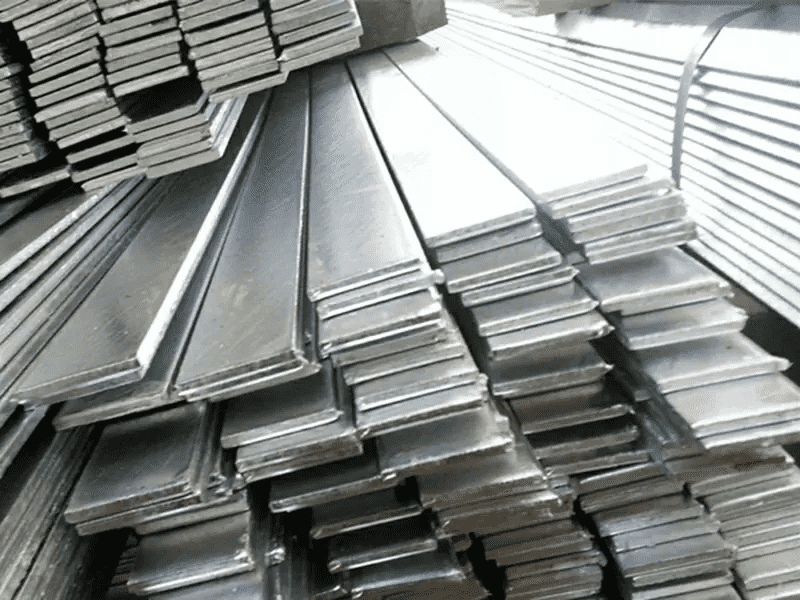

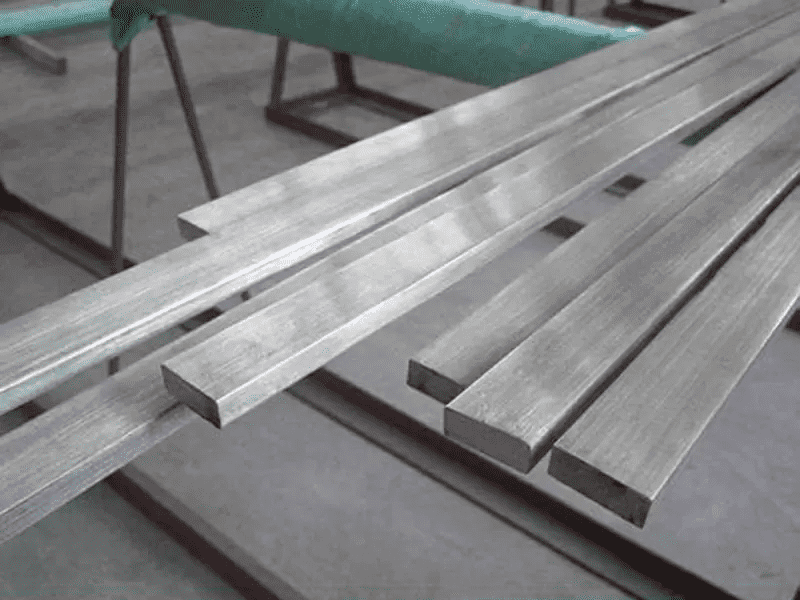

Stainless steel flat bar is a long strip of steel made of high-quality stainless steel materials through precision processing. It has the characteristics of rectangular cross-section, straight edges and uniform thickness. With its excellent corrosion resistance, high strength and aesthetics, it is widely used in machinery manufacturing, architectural decoration, rail transportation, food and medical, chemical equipment and other fields. It is an ideal basic material for industrial and civil fields.

Core advantages

Various materials and excellent performance

Material options: 304, 304L, 316, 316L, 201, 430 and other mainstream stainless steel grades to meet the needs of different environments.

304/316 series has excellent acid and alkali resistance and oxidation resistance, and is suitable for high temperature, humid and corrosive environments; 430 series is economical and practical, suitable for general anti-rust scenes.

Complete specifications, flexible customization

Conventional thickness: 1.5mm~20mm; width: 10mm~200mm; length: can be customized according to needs (usually 6 meters).

Support non-standard size customization to meet special engineering design needs.

Exquisite craftsmanship and reliable quality

Molding by cold rolling or hot rolling process, the surface finish reaches different levels such as 2B, BA, NO.4, and special treatments such as wire drawing and mirror can also be provided.

Strictly control the chemical composition and mechanical properties, in line with international standards such as GB/T 1220, ASTM A276, JIS G4303.

Widely used and strong adaptability

Industrial field: mechanical equipment frame, mold substrate, conveyor belt bracket, precision parts, etc.

Architectural decoration: stair handrails, door and window edging, curtain wall keel, indoor and outdoor decorative strips, etc.

Special industries: food processing equipment, medical equipment, ship accessories, environmental protection engineering structural parts, etc.

Production process and quality control

Raw material selection: high-quality stainless steel coils from large steel mills are selected to ensure the purity of the material.

Precision rolling: The dimensional tolerance (±0.1mm) is controlled by high-precision rolling mills to ensure product consistency.

Surface treatment: The pickling and passivation process improves the rust prevention ability, and the polishing process realizes the diversified appearance requirements.

Strict testing: spectrometer detects ingredients, hardness tester and tensile testing machine verify mechanical properties, and full-process quality control ensures zero defects.

Service Commitment

Quick response: supports small batch samples and large-scale orders, with flexible delivery cycles.

Professional guidance: provides material selection suggestions, processing technology support and industry application solutions.

Logistics guarantee: adopts moisture-proof and anti-collision packaging, efficient distribution across the country, and supports export customs declaration.

Reasons for choosing us

Ten years of industry experience: focusing on stainless steel profile production, mature and reliable technical team.

One-stop service: from material selection, cutting to deep processing, efficient cooperation throughout the process.

Environmentally friendly and sustainable: 100% recyclable materials, production processes meet green manufacturing standards.

Reviews

There are no reviews yet.