Product description

Product Overview

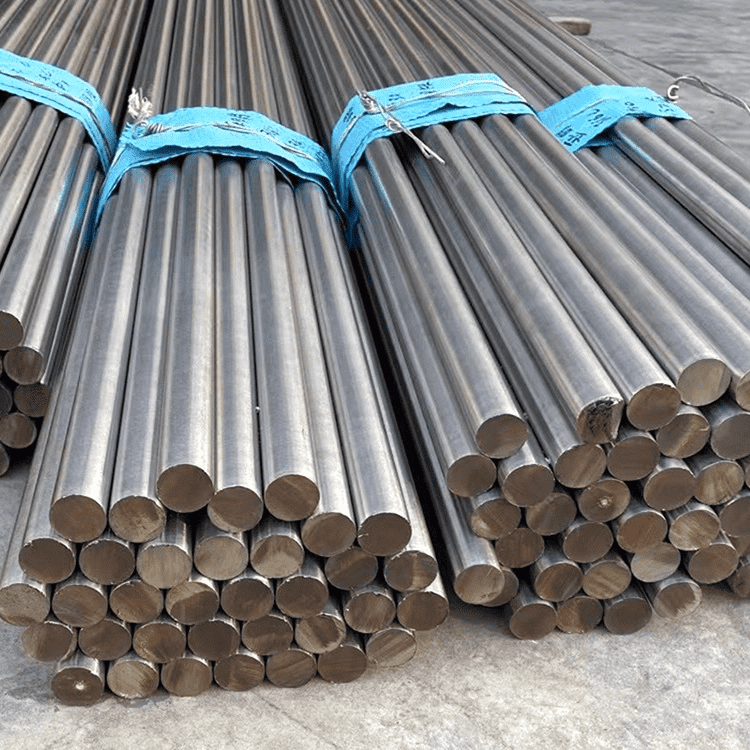

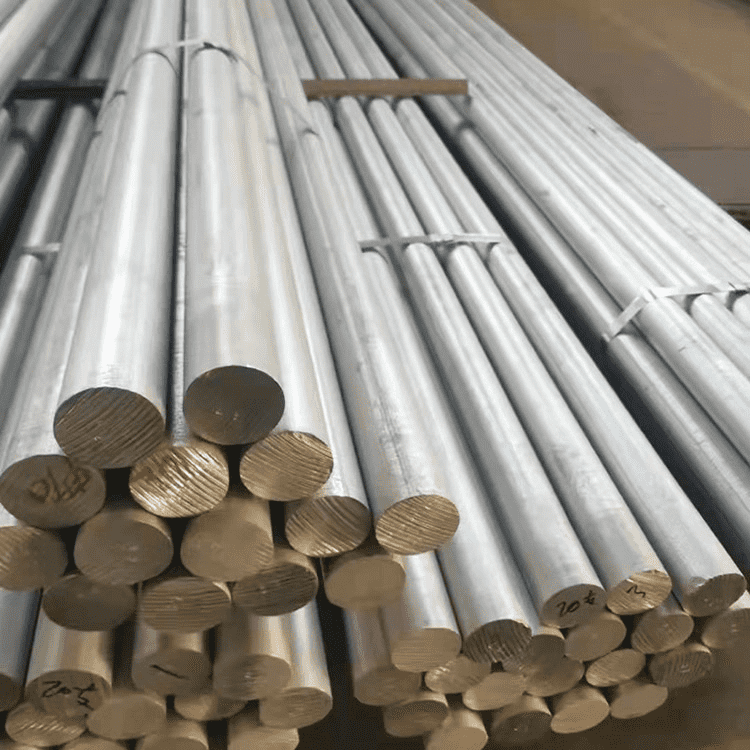

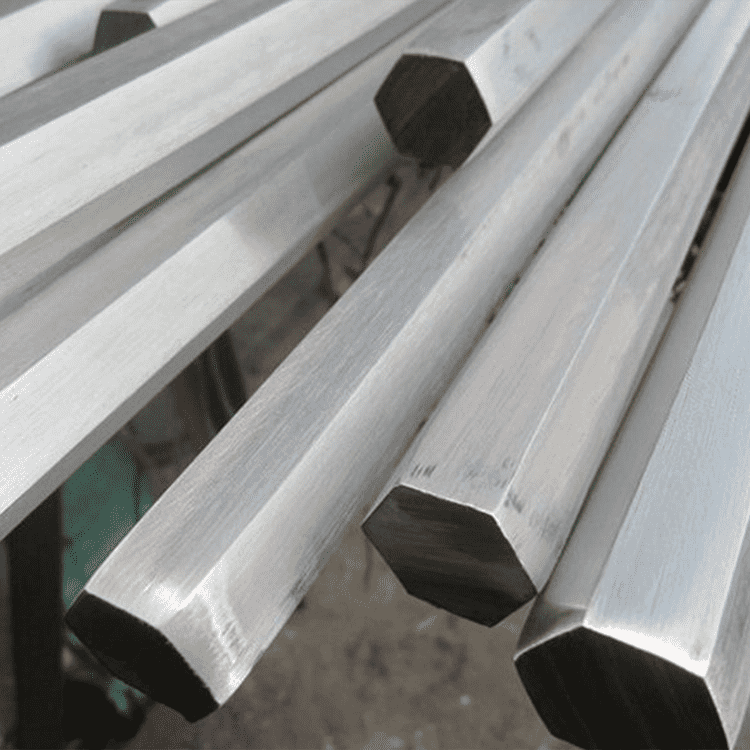

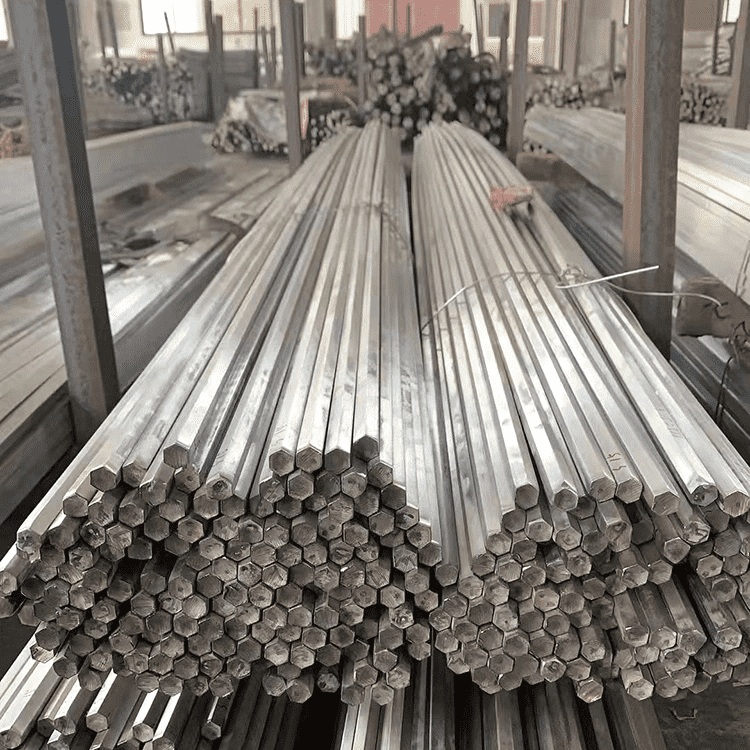

Stainless steel round bar is a long steel bar with a round cross section made of high-quality stainless steel by hot rolling, cold drawing or forging. It has the characteristics of smooth surface, high dimensional accuracy and excellent mechanical properties. With its excellent corrosion resistance, high strength and good processing adaptability, it is widely used in machinery manufacturing, automobile industry, petrochemical industry, medical equipment, aerospace and other fields. It is one of the core materials for high-end equipment manufacturing and precision parts processing.

Core advantages

- Diverse materials and comprehensive performance

Common materials: 304, 304L, 316, 316L, 321, 2205 duplex steel, 430, etc., covering austenite, martensite and duplex stainless steel series.

316L: Chloride corrosion resistant, suitable for marine environment and chemical equipment; 304: Strong versatility, suitable for food, medical and daily equipment; 2205 duplex steel: High strength and corrosion resistance, used in harsh working conditions.

- Complete specifications, support customization

Diameter range: hot-rolled round steel Φ5mm~Φ250mm; cold-drawn round steel Φ1mm~Φ50mm (high precision ±0.05mm).

Flexible length: conventional straight bar length is 3 meters to 6 meters, and can be customized with extra-long sizes or precision-cut sections.

- Exquisite workmanship and stable quality

Hot rolling process: high-temperature rolling forming, dense organization, suitable for large diameter and high-strength demand scenarios.

Cold drawing process: surface finish reaches Ra≤0.8μm, dimensional tolerance is precise, suitable for precision parts processing.

Surface treatment: supports bright surface (mirror), matte, pickling, sandblasting and other treatment methods to meet different appearance and rust prevention requirements.

- Complete certification, international standards

Comply with GB/T 1220, ASTM A276, DIN EN 10088 and other standards, provide material certificate (MTC) and third-party test report.

Application fields

Mechanical manufacturing: high-strength structural parts such as shaft parts, transmission parts, bolts, nuts, etc.

Chemical energy: reactor stirring shafts, pump valve accessories, pipeline supports, corrosion-resistant and high-temperature resistant.

Medical equipment: surgical instruments, implant substrates, and testing equipment brackets to meet biocompatibility requirements.

Automobile and shipbuilding: engine parts, ship anchor chains, exhaust system components, adapting to complex environments.

Architectural decoration: artistic sculptures, railing columns, curtain wall connectors, both beautiful and durable.

Production process and quality control

Raw materials are strictly selected: first-class cold/hot-rolled steel billets from well-known steel mills such as Taigang and Baosteel are used to ensure pure ingredients.

Precision machining:

Hot-rolled round steel: temperature-controlled rolling, eliminating internal stress, and ensuring mechanical properties.

Cold-drawn round steel: multi-pass drawing + annealing process to improve surface finish and dimensional consistency.

Full process detection:

Chemical composition analysis (spectrometer), hardness test (Rockwell/Vickers), metallographic structure observation.

Mechanical property tests such as tensile strength, yield strength, and elongation.

Surface flaw detection (eddy current detection, magnetic particle detection) eliminates defects such as cracks and bubbles.

Service commitment

Fast delivery: regular specifications are shipped directly from stock, and customized products are delivered in 7-15 days.

Technical support: Provide guidance on material selection, processing technology and surface treatment solutions.

Quality assurance: Support third-party inspection, free return and exchange for quality problems during the warranty period.

Global supply: export standard packaging (wooden box/bundling + anti-rust film), support DDP, FOB and other trade methods.

Reasons to choose us

15 years of deep cultivation in the industry: focus on the research and development and production of stainless steel profiles, serving more than a thousand customers.

One-stop solution: from round steel supply to precision cutting, heat treatment, surface processing, full-process supporting services.

Green smart manufacturing: low-carbon and environmentally friendly production throughout the process, 100% recyclable products, help sustainable development.

Reviews

There are no reviews yet.