Product description

Product Overview

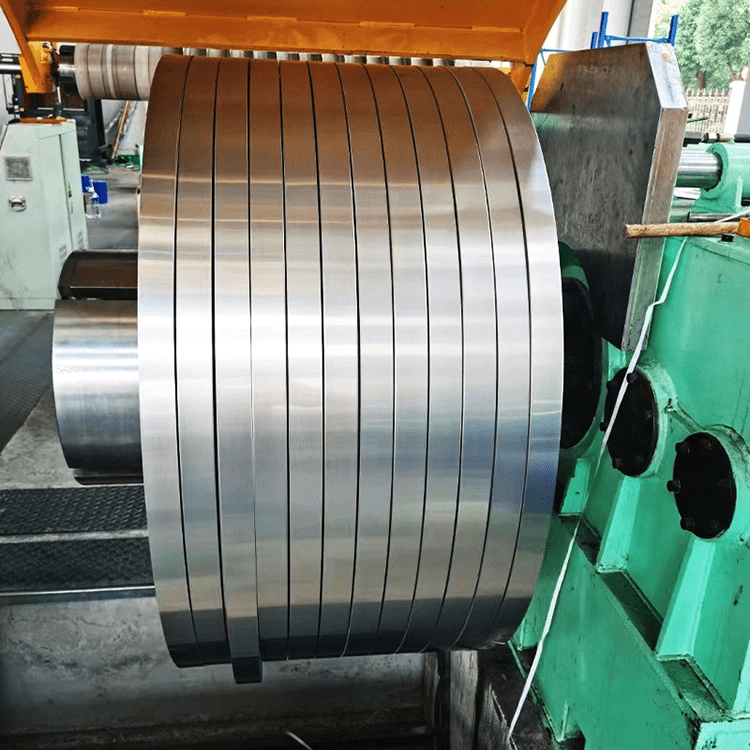

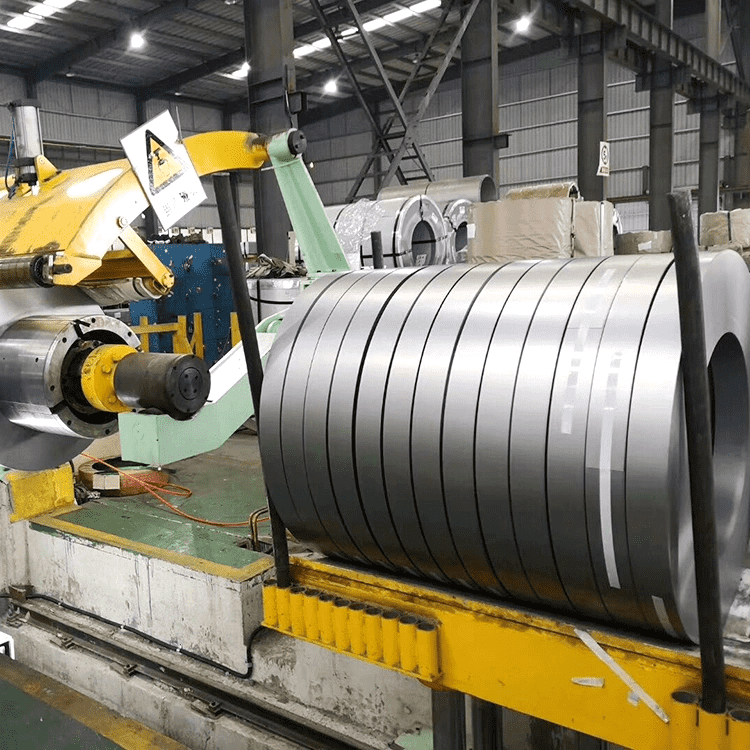

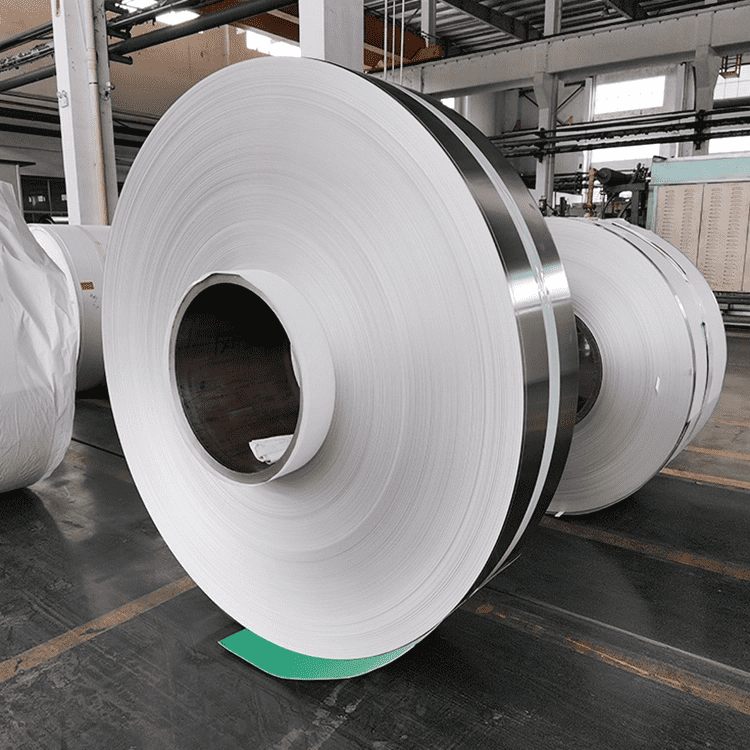

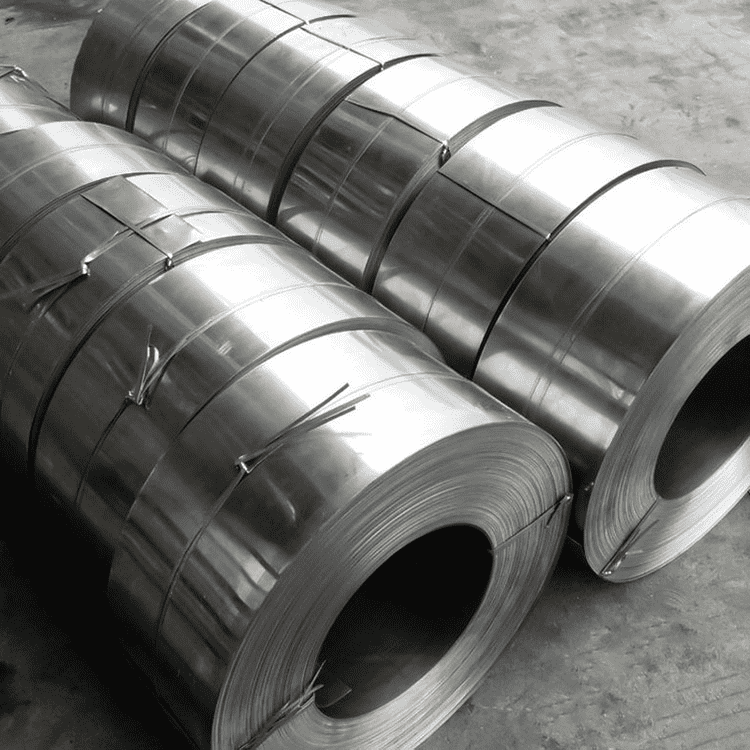

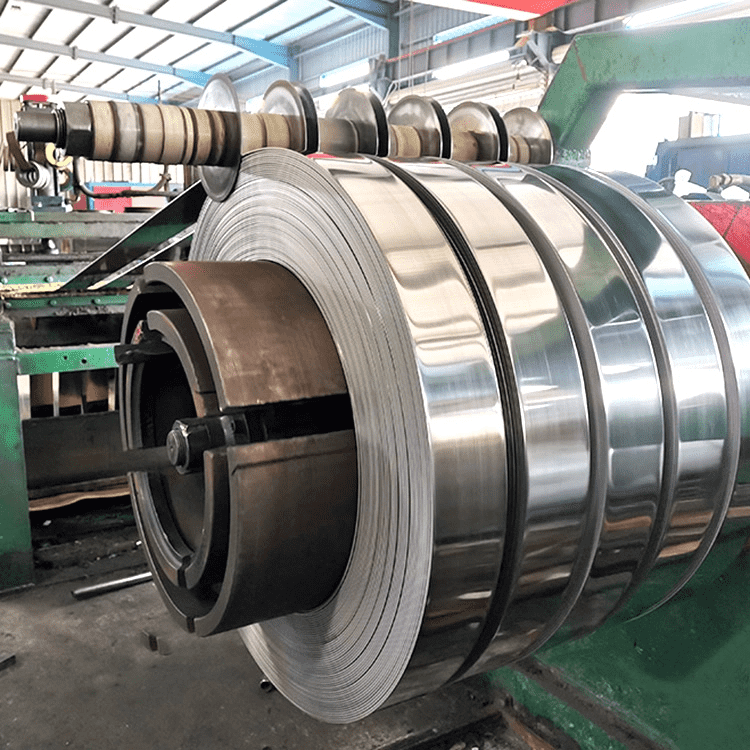

Stainless steel strip is a thin and wide strip material made of high-quality stainless steel through precision cold rolling or hot rolling process. It has the characteristics of flat surface, uniform thickness and good ductility. With its excellent corrosion resistance, high strength and diversified surface treatment process, it is widely used in electronic appliances, medical equipment, auto parts, precision stamping, architectural decoration and other fields. It is an ideal choice for high-end manufacturing and precision processing.

Core advantages

- Diverse materials and performance adaptation

Mainstream materials: 304, 304L, 316, 316L, 430, 201, etc., to meet the needs of different environments.

304/316 series: acid and alkali resistant, anti-oxidation, suitable for food, medical and chemical equipment;

430 series: economical rust prevention, suitable for ordinary scenes such as home appliances and decoration;

High hardness martensitic steel (such as 420J2): used for knives and precision machinery parts.

- Flexible specifications, efficient customization

Thickness range: 0.03mm~3.0mm (cold-rolled ultra-thin strip can reach 0.03mm, hot-rolled strip 1.0mm~3.0mm).

Width range: 10mm~1500mm, supports personalized processing such as striping and cutting.

Surface state: 2B (matte), BA (bright), No.4 (brushed), 8K (mirror), HL (hairline), etc., to meet diverse appearance requirements.

- Exquisite craftsmanship and reliable quality

Cold rolling process: high-precision rolling, strict tolerance control (±0.005mm), smooth and flawless surface.

Annealing treatment: eliminate internal stress, improve material ductility and processing performance.

Strict quality control: in line with GB/T 3280, ASTM A240, JIS G4305 and other standards, provide material report (MTC) and SGS certification.

- Wide application and strong adaptability

Electronic appliances: battery pole pieces, shielding covers, connectors, precision springs, etc.;

Automotive industry: exhaust system gaskets, sensor housings, decorative strips, etc.;

Medical devices: surgical instruments, testing equipment components, implant substrates;

Architectural decoration: elevator panels, kitchen countertops, advertising signs, etc.

Production process and quality control

Raw materials are strictly selected: first-class steel coils from well-known steel mills such as Baosteel and Taigang are used to ensure pure ingredients.

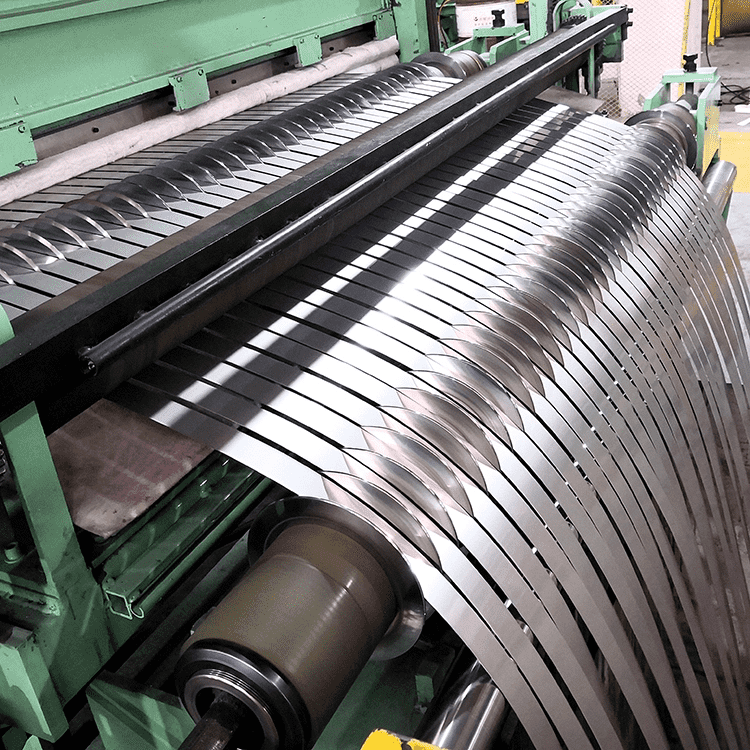

Precision rolling:

Cold-rolled strip: multi-pass rolling + annealing process to achieve ultra-thin and high precision (tolerance ±0.005mm);

Hot-rolled strip: temperature-controlled rolling to ensure stable mechanical properties.

Surface treatment:

Pickling and passivation: enhance corrosion resistance and remove oxide layer;

Polishing/brushing: customized surface texture to improve aesthetics.

Full process inspection:

Thickness/width laser measuring instrument to ensure accurate size;

Surface defect detection system (CCD visual inspection) to eliminate scratches and pitting;

Performance verification such as salt spray test, hardness test, tensile test, etc.

Service Commitment

Quick response: Regular specifications are available in stock, and customized orders are delivered in 7-15 days.

Technical support: Provide stamping suggestions, surface treatment solutions and industry application guidance.

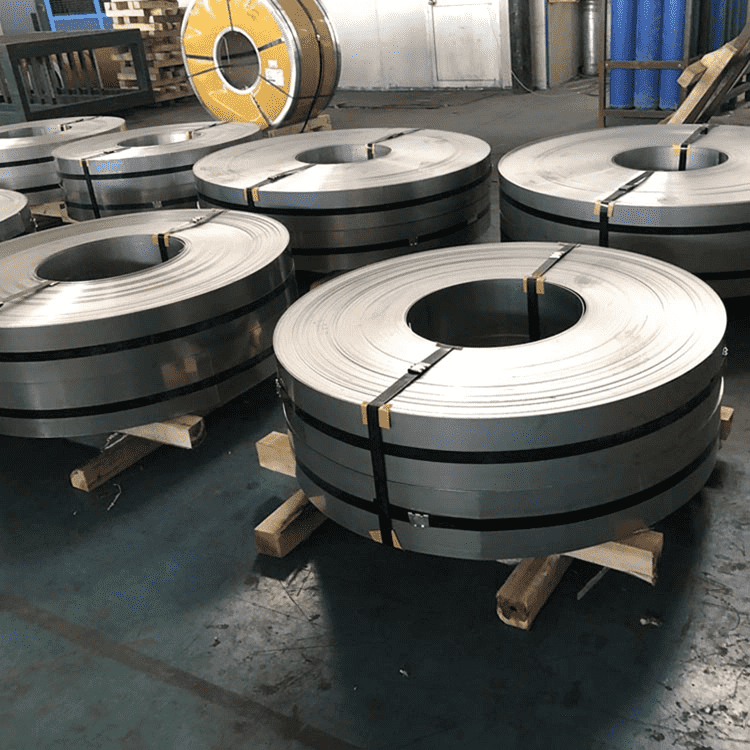

Packaging guarantee: Moisture-proof and scratch-proof PE film + wooden box/steel coil packaging to ensure zero damage during transportation.

Global supply: Support export customs declaration, provide COC certificate, certificate of origin and other documents.

Reasons for choosing us

Technological leadership: 10 years of focus on stainless steel strip production, with imported rolling mills and intelligent testing equipment.

Cost optimization: Large-scale production reduces marginal costs, and the cost-effectiveness is leading in the industry.

Environmental certification: The production process complies with RoHS and REACH standards, and the products are 100% recyclable.

After-sales worry-free: Provide 12-month warranty and lifelong technical consulting support.

Reviews

There are no reviews yet.