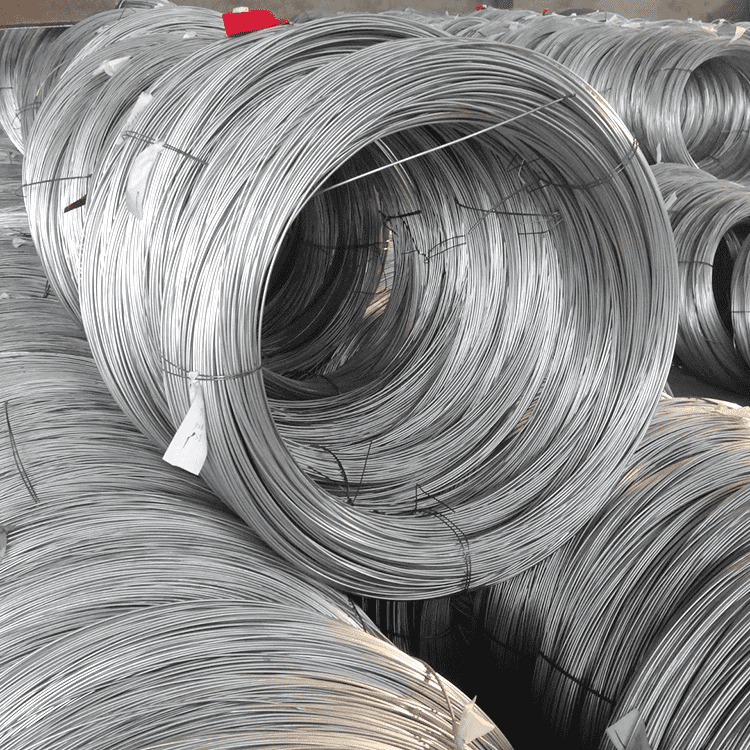

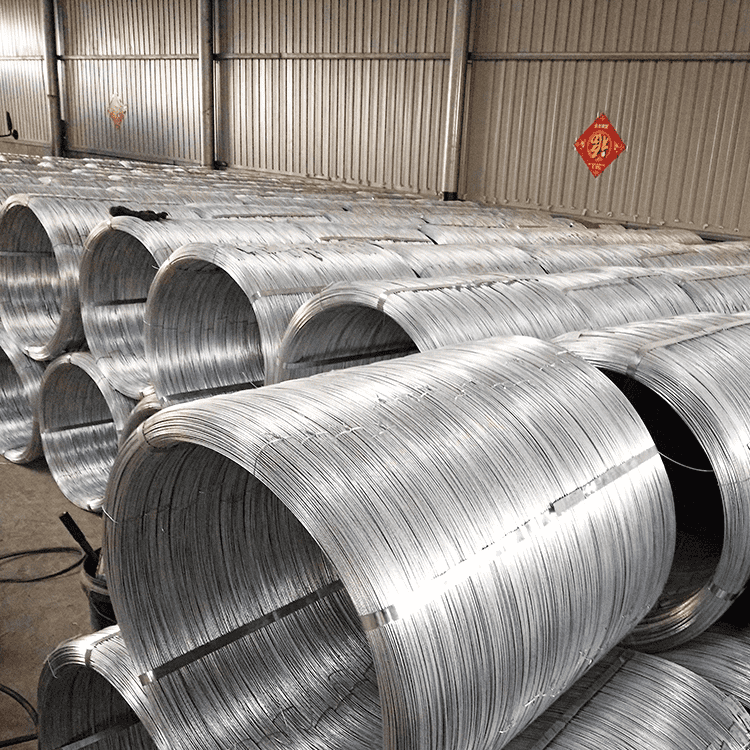

Product description

Stainless steel wire is a slender metal wire made of stainless steel as the base material, with excellent corrosion resistance, high strength and ductility. Due to its good performance, stainless steel wire is widely used in many fields, including construction, automobile manufacturing, medical equipment, aerospace, etc.

Material characteristics

Corrosion resistance: Stainless steel wire is not easy to rust after long-term use in acid, alkali, salt and other media, and is especially suitable for industrial environments.

High strength: Stainless steel wire has high tensile and bending strength, suitable for various load-bearing and stretching scenarios.

Smooth surface: After polishing or coating, the surface is smooth to reduce friction resistance.

High temperature resistance: Some stainless steel wires can be used in high temperature environments.

Profile characteristics

Strong plasticity: The surface of stainless steel wire is smooth and easy to process into various shapes and structures.

Lightweight design: Compared with ordinary steel wire, stainless steel wire has higher strength and lighter weight, suitable for application scenarios that require lightweight materials.

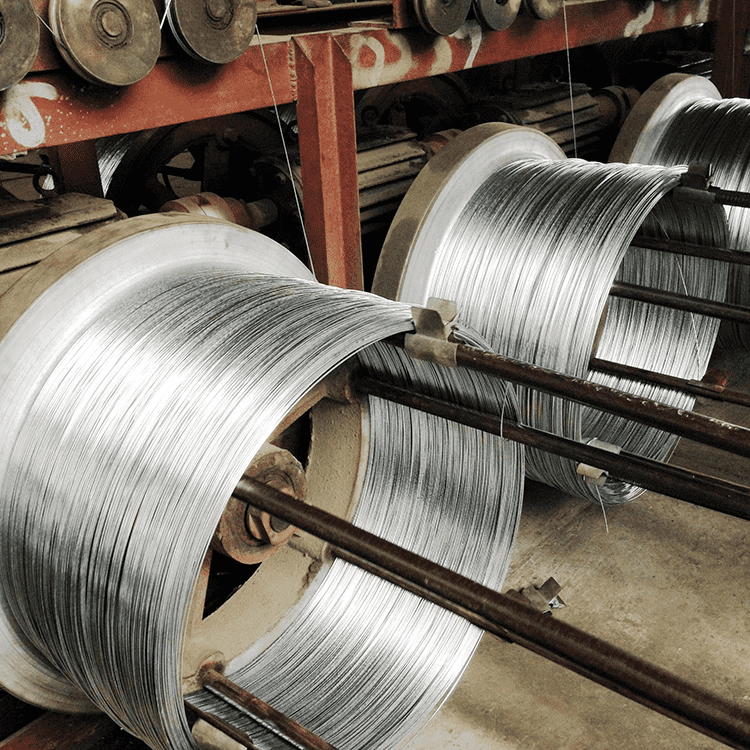

Common models and specifications of stainless steel wire

Based on shape, diameter and purpose, stainless steel wire is usually divided into the following types:

Round steel wire

Common diameter: 0.3mm – 5mm (customizable)

Common surface treatment:

Smooth surface: suitable for scenes requiring a smooth surface.

Coating protection: Further extend the corrosion resistance through coating (such as hot-dip galvanizing or hot-dip nickel).

Flat steel wire

Common thickness: 0.5mm – 10mm

Used for structural applications and decorative purposes.

Square steel wire

Common side length: 4mm – 16mm (customizable)

Commonly used in building structures and frame parts.

Hexagonal steel wire

Common side length: 5mm – 20mm

Applicable to mechanical manufacturing and structural engineering.

Angle steel wire

Common side width: 10mm – 30mm (customizable)

Used for construction and mechanical manufacturing.

Rounded steel wire

Common diameter: 4mm – 20mm

The surface treatment is usually smooth or coated surface, suitable for scenes requiring higher strength and durability.

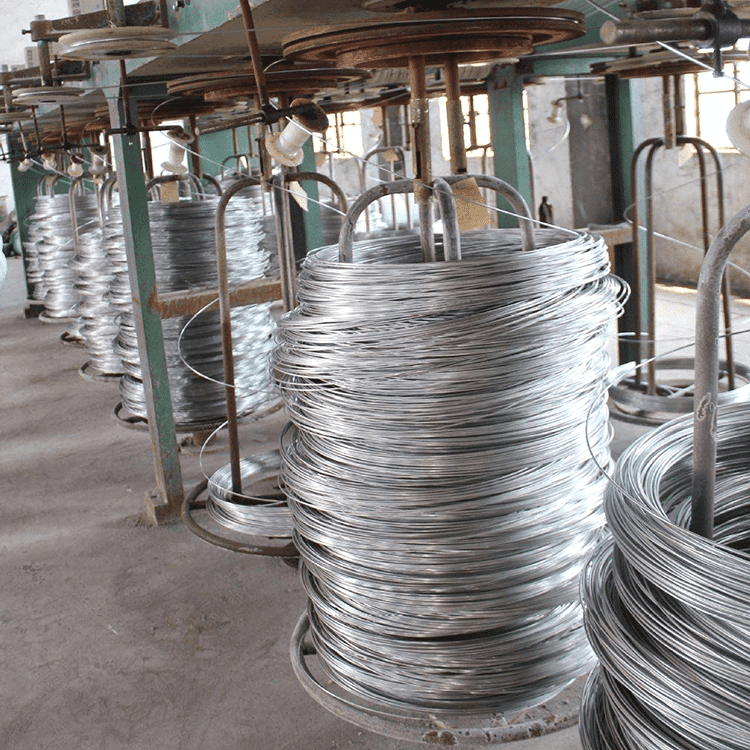

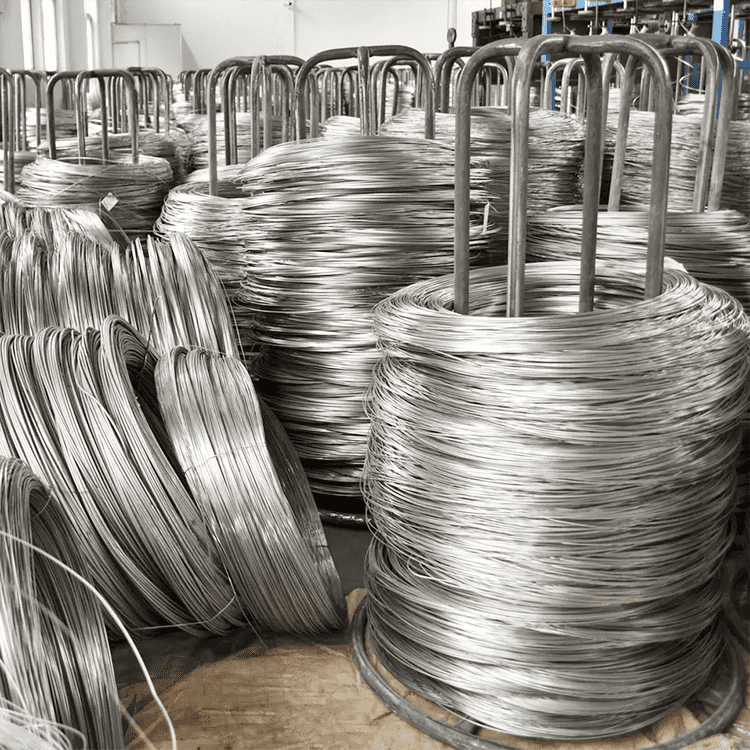

Common surface treatment methods

Hot-dip galvanizing: Improve corrosion resistance by dipping in zinc.

Hot-dip nickel: Suitable for occasions with higher requirements (such as food processing equipment).

Coating treatment: Increase surface protection through chemical or physical methods.

Application scenarios of stainless steel wire

Construction field

Construction structure, decorative materials, canopy brackets, etc.

Automobile manufacturing

Frame skeleton, headlight bracket, suspension system, etc.

Medical equipment

Anti-corrosion parts, medical device frames, etc.

Aerospace

Structural parts, connectors, etc., due to their high strength and corrosion resistance.

Daily necessities

Commonly used in lightweight scenes such as ropes and hand-cranked door handles.

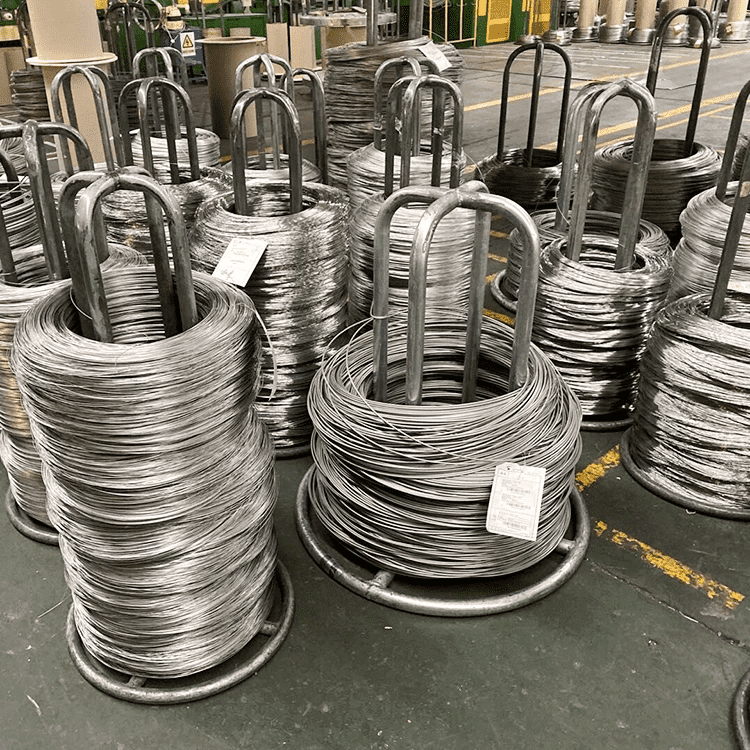

Advantages of stainless steel wire

Corrosion resistance: It can maintain its appearance and strength for a long time even in harsh environments.

High strength and lightweight: Compared with ordinary steel wire, stainless steel wire has high strength and light weight.

Good processability: After smooth surface or coating treatment, it is easy to process into various shapes.

Strong applicability: Suitable for a variety of application scenarios, including construction, automobile manufacturing and medical equipment.

Reviews

There are no reviews yet.